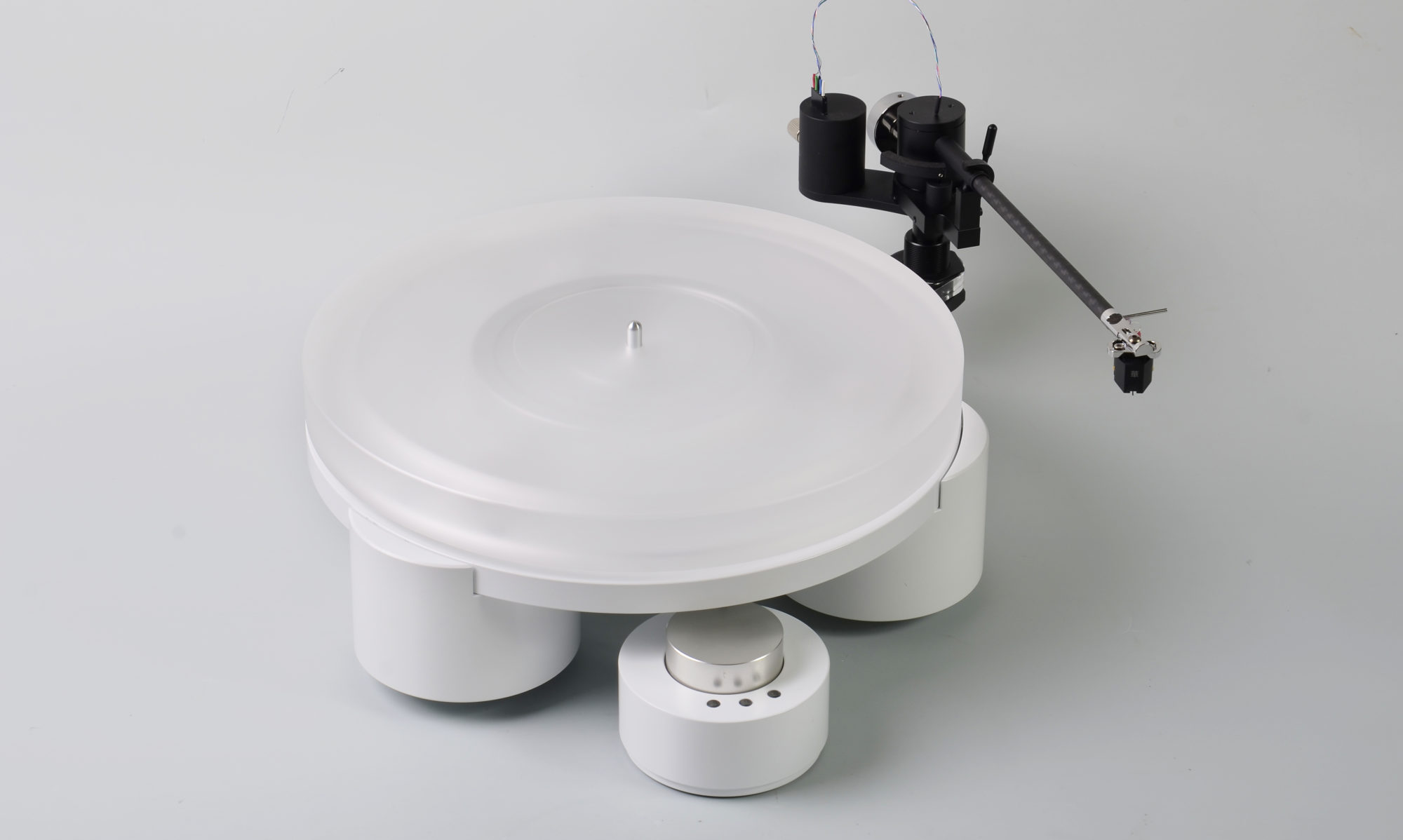

Tien audio Vacuum vinyl flattener

1. Why vinyl need flaten

Vinyl analog discs are typically composed of polyvinyl chloride and are susceptible to warping and other forms of damage due to their sensitivity to heat. Therefore, it is essential to employ proper storage methods to prevent such damage. Addi-tionally, aging can also result in vinyl record warping, and hence extra caution is necessary. Fortunately, by applying uniform pressure and gentle heat to the vinyl, the Disc Flattener can restore it to its original flat state while preserving audio quality.

2. Why use vaccum

The use of vacuum technology in vinyl flattening machines has become increasingly popular due to its effectiveness. Unlike the traditional use of gravity to press, which is limited when faced with uneven records, vacuum technology can reach up to 1 kg/cm2, providing a more effective solu-tion. Additionally, vacuum technology allows for heavy pressing without directly touching the track, reducing the weight of the machine.

3.Design

To ensure even heating and a constant temperature, flattening machines use microcomputer constant temperature control with thin film heating sheets. This technology allows for the vinyl to be heated evenly, reducing the risk of uneven pressing and ensuring the best possible sound quality.

3.Design

To ensure even heating and a constant temperature, flattening machines use microcomputer constant temperature control with thin film heating sheets. This technology allows for the vinyl to be heated evenly, reducing the risk of uneven pressing and ensuring the best possible sound quality.

4.Program

Our vaccum flattening machines offer two different working modes:

- Heating mode and flattening mode. Heating mode heats and flatten vinyl, with three different times to choose (1.5/2/2.SHrs).

- Tempering mode, on the other hand, is used to stabilize the material. When vinyl is produced, the material is pressurized and instantly cooled above 110 degrees, leading to unstable crystallization. To solve this issue, the vinyl record is heated to 57 degrees for 30 minutes and then slowly cooled for 30 minutes to achieve the tempering process. This ensures a stable crystallization and optimal sound quality

Specification

- Supply voltage: 48V DC 5A

- Power consumption: 200watts

- Origin: Taiwan

- Size: 40/40/10cm

- Weight: 6kg

- Heating temperature: 57 degrees c